Energy

We supply parts and special components to the world's leading turbine and generator manufacturers in the power and thermal energy sector. We use state-of-the-art manufacturing equipment, technology, measurement and inspection equipment to ensure the highest level of quality in the parts we supply. The result is fast delivery of quality parts to meet the exact requirements of our customers.Parts for gas, steam and water turbines

Designed for extreme conditions

Our components are used in the most extreme conditions. This is reflected in the resulting quality, precision, workmanship and materials used. We focus on supplying parts for new projects as well as for service and repair organizations with deliveries worldwide. We use many decades of experience and expert technical knowledge and skills to satisfy our customers.

Precision manufacturing and inspection processes

Our components are used in the most extreme conditions. The resulting quality, precision, workmanship and materials used match this. We focus on supplying parts for new projects as well as for service and repair organizations with deliveries worldwide. We use many decades of experience and expert technical knowledge and skills to satisfy our customers.Modern machining technology

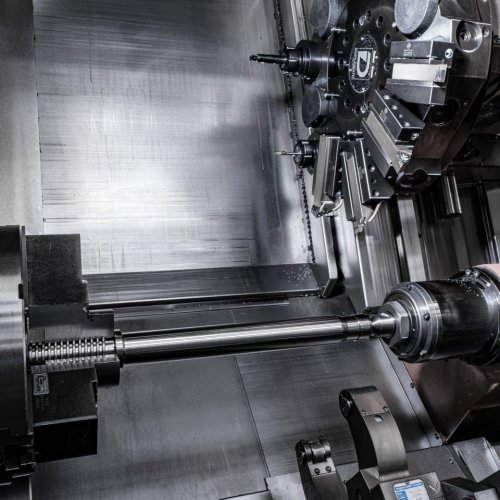

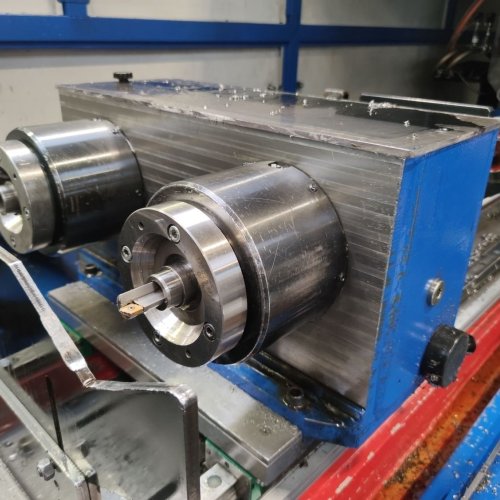

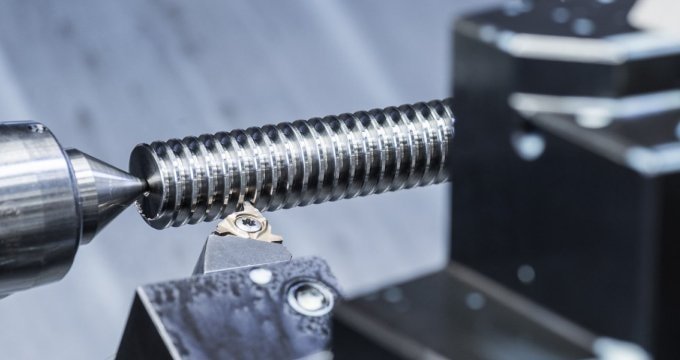

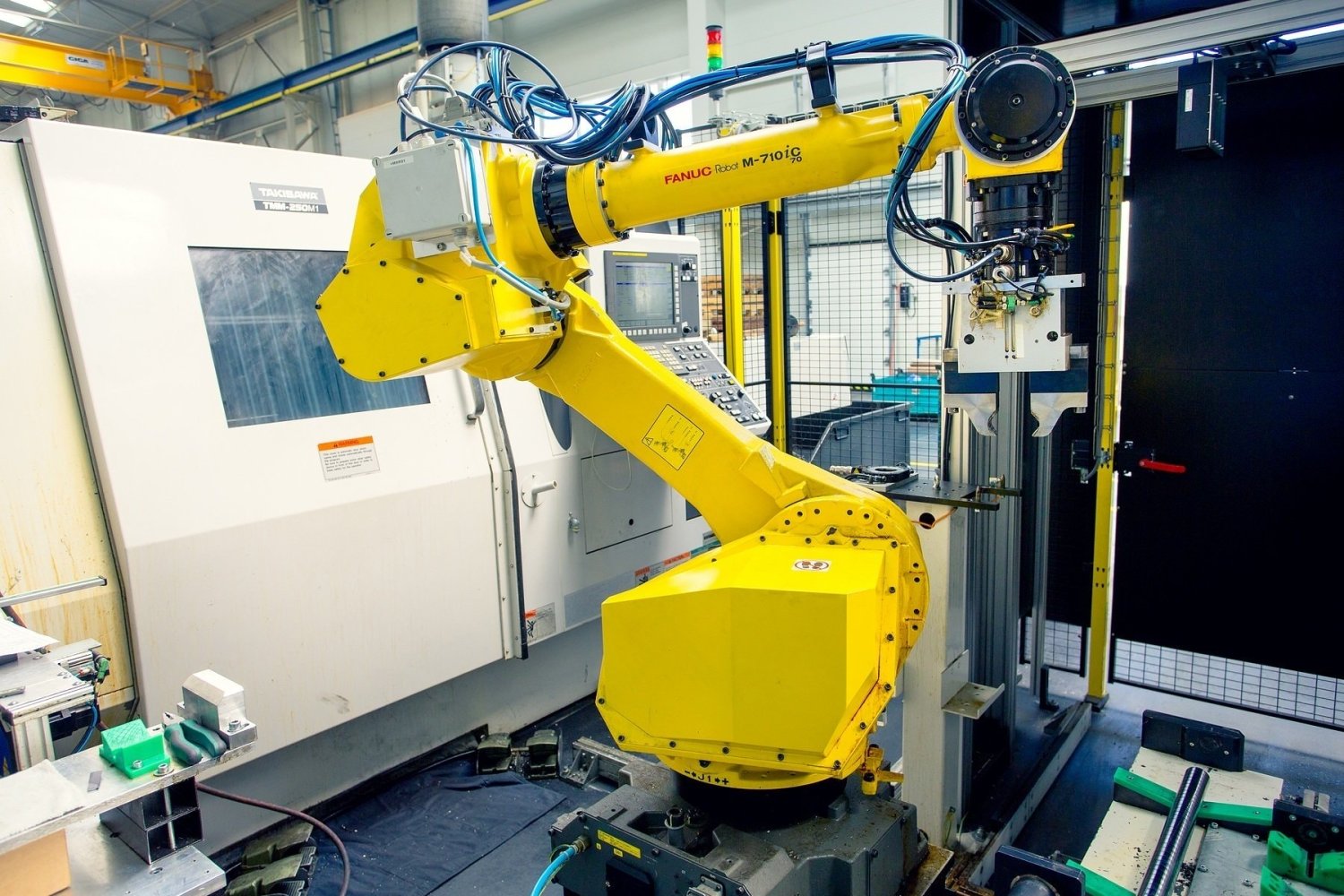

At Sanborn, we use the latest machining technologies for CNC turning, milling, grinding and drilling. We have both horizontal and vertical machining centres (see our machine park for an overview). We also use special processes such as thread rolling, deep drilling or diamond belt grinding during production. During and after production operations, we place great emphasis on the quality of the parts produced. Each production step is accompanied by control mechanisms and the results are fully documented.

Products

- Nuts screws

- Sealing rings

- Washers

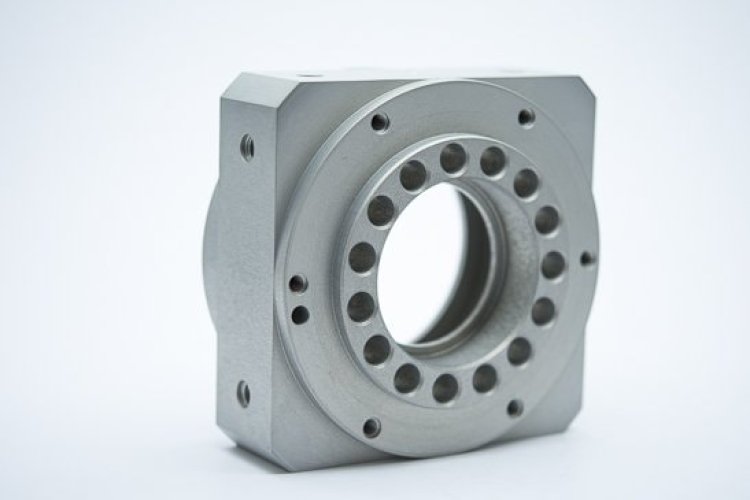

- Housings

- Flanges

- Valve blocks and heads

- Tie bolts

- Module bolts

- Coupling bolts

- Gas burner parts

- Oil fitting

- Inlet parts

- Cylinders

- Sleeves

Materials

- 21CrMoV6-7

- 40CrMoV4-6

- AISI422

- X22CrMoV12-1

- X7CrNiMoBNb16

- NITRONIC 50

- 17-4PH XM19

- DUPLEX AND SUPERDUPLEX GRADES

- Alloy A286

- Hastelloy X

- Nimonic 80A

- Inconel 625

- Inconel 718

- Inconel 725

- Inconel 825

- Inconel 925

Coatings

- FlZn

- Nitriding

- Xylan

- Cu, Zn coating

- MnPh coating

- MoS2 coating

We deal with precision machining of common and special materials using progressive CNC technologies - turning, milling, grinding and drilling. We have both vertical and horizontal machining centers.High precision machining

We are carefully prepared for your orders

High precision

Specialists in complex parts

High quality machinery

Machining up to 4 m

Expert know-how

Comprehensive quality assurance

Short delivery times

Maintaining technological development

Sanborn is equipped with a range of modern CNC machine tools covering a wide range of workpiece sizes and technological capabilities. Commonly machined part sizes range from 10x10mm to 4m long parts.

Modern machinery park

Our products have applications underwater, on land, in the air and in space.

We supply companies all over the world